From residential window air conditioning units to commercial HVAC systems for offices and buildings, there is a steady stream of claims and litigation arising from the design, installation, and service of these mechanical systems. Oftentimes, component part failure contributes to the loss.

Some cases involving HVAC focus on the technical aspects of sizing/rating the system (needs for heat or cooling depending on size of living space). Other cases focus on resultant fire property loss or personal injury associated with exposure to mold, carbon monoxide, electric shock and sometimes workplace safety operating around this type of equipment. But perhaps the most typical claim results from a water leak from an HVAC unit floods a space containing significant valued property loss.

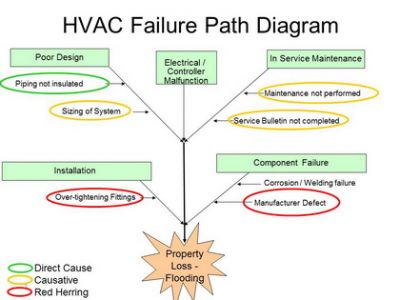

A forensic engineer investigates these types of claims and evaluates contributing factors to the loss and ultimately determines liability for its cause. The below pictogram is referred to as a ‘fishbone diagram’ in our office and is tool our engineers use to analyze contributing factors. Let’s take the example of the water loss with origin as the HVAC system. In this scenario, there are allegations of faulty design of the HVAC system. Another allegation is that piping froze and then thawed causing the flooded space. Of course, installers and maintainers of the HVAC system are also called in as possible responsible parties. Oftentimes, a component within the system (ie. Coil, valve, etc.) fails due to corrosion, bad weld, or possibly a manufacturer’s defect. Sometimes, a controller malfunction or electrical component is of concern and brought into the possible responsible parties. The investigating engineer must take all these allegations into consideration and confirm how they could possibly contribute to the loss. A fishbone diagram helps demonstrate how various factors could contribute to the resultant loss. Ultimately, the engineer must establish his/her opinion as to a reasonable degree of engineering certainty.

Within our 25 plus years of investigative engineering, we find that HVAC and refrigeration failures are typically a function of one of three things: potential manufacturer defect, system design flaw or improper maintenance.”

From the manufacturer defect perspective, engineers will inspect the failed equipment to determine the cause and origin point. Once the point is located, the engineer will examine and test the component or an exemplar to make sure that in fact the failure point operated as stated by the manufacturer and that there weren't any contributing factors. The second area to examine, in the event of failures, is the system design of the HVAC and refrigeration system. Manufacturers produce ratings for systems and what HVAC and Refrigeration units are capable of handling. These ratings or standards are published in documentation and regulated by such groups as the Air Conditioning Refrigeration Institute (ARI) www.ARI.org. If installers and subsequent sub-contractors violate these standards and design requirements such as improper piping and sizing and non-recommended materials, systems can overheat or fail to perform causing a complete system failure. Engineering experts will typically examine the design plan of the system to make sure that manufacturer guidelines were followed and that all sizing calculations and proper materials were used in the installation of the system.

The last area for examination in HVAC failures is maintenance. Maintenance can typically be from air filters not being replaced, heat exchanger not being cleaned, system leaks to not contacting the manufacturer when the system operates in an abnormal operation. System leaks where Freon, which is heavier than air and displaces oxygen, can fill a room and suffocate a person as opposed to Ammonia which is used in refrigeration can become explosive is leaked and it finds an ignition source. Maintenance to HVAC systems, especially in extreme hot and cold weather, is crucial to preventing accidents.

Featured Engineer: Gregory J. Paulsen, P.E., CPE, CFEI, Mechanical Engineer

Submit a case or claim online.

Contact a CED Engineer in your region.